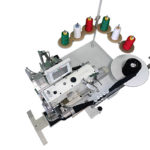

JT418HS

Automatic waistband machine for jeans and similarThe JT418HS sewing unit is an automatic machine for the application on jeans and similar of single or double waistband belts, in continuous or single piece.

The machine is equipped with:

• KANSAI sewing head, 4 needle ¼”-1”-¼”, cylindrical base, chain stitch, with lower feed and needle feed

• Adjustable speed electronic synchronized puller

• Rear clamp that guarantees the execution of a straight cut at the beginning and the end of the belt

• Special JAM system which makes possible to create straight and curved waistband

• Programmable initial and final belt unstitching

• Belt feeding with roll holder

Suitable for medium/heavy fabrics

The electronic synchronization of the puller with the alternating feed ensures constant stitch length as the speed and thickness change

All machine functions are controllable and easily programmable through the intuitive JAM touch screen operating panel.

Optional devices

Unstitching ¼”-1″-¼” for only 1st and 2nd

needle

Specifications

| Sewing head |

KANSAI 4 needles chain stitch |

| Control unit |

PLC + JAM touch screen |

| Feeding system |

Lower and needle feed + Synchronized puller |

| Sewing speed |

Up to 4000 rpm |

| Stitch lenght |

2.10 – 6.40 mm |

| Belt cut height | Max 75 mm |

| Power source |

220 Vac – 50/60 Hz |

| Electric consumption | Max 1.1 kW |

| Air source | 6 bar |

| Air consumption | Max 0.5 l/cycle |

| Dimension and weight |

126x74x175(H) cm – 170 kg |