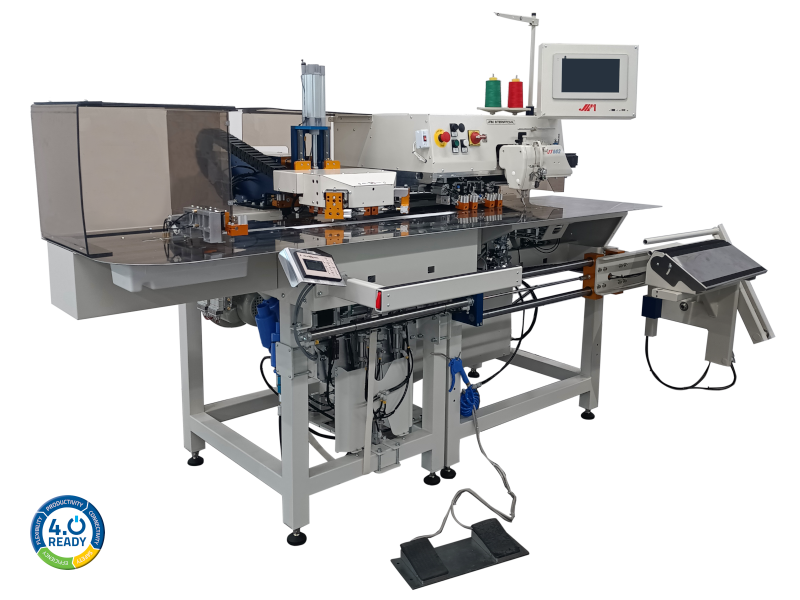

JT863M

Automatic pocket setter with folding group for shirt, knitting, swim shorts and similarThe unit JT863M is an automatic programmable area machine for the application of patch pockets on shirt, knitting, swim shorts and similar, with a new folding unit from 65×65 to 270×270 mm and an automatic stacker.

SEWING HEAD

Equipped with a JAM INTERNATIONAL lockstitch sewing head with direct motors and thread trimmer; the electric axis allows to process the pieces wider than average

PROGRAMMABLE ELECTRONIC THREAD TENSION

Thread tension electronically controlled and settable through the touch screen. It is possible to program different tensions within the pocket sewing cycle.

THREAD EXTENSION/THREAD LOCK

The thread extension / thread lock device allows to set through the touch screen the length of the residual thread after the thread trimmer and to obtain maximum quality at the next seam beginning.

5-MOVEMENTS FOLDING GROUP

It gives the possibility to sew nonstandard pockets, such as the square pocket or with rounded corners, with excellent quality.

The cold folding system guarantees high quality production standards even on the most difficult fabrics such as stretch, super stretch and knitwear.

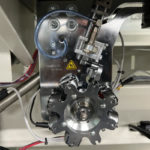

POCKET JIG

The pneumatic release allows changing the pocket jig in a few seconds.

Thanks to a patented system, the customer has the possibility to create the templates independently in a simple way and by the use of common tools.

TOUCH SCREEN

The intuitive 10″ touch screen user interface allows:

• creation of sewing programs simply by inserting the pocket dimensions or by importing DXF files containing the pocket profile

• uploading via USB port of sewing programs made by our BDCAD software

• editing of any kind on existing programs

• failure self-diagnostic system

• trouble shooting and software updates via remote

• production statistics visualization (which can also be consulted remotely).

OTHER MACHINE USES

The machine can also be used for:

• ornamental stitching

• application of small pockets / coin pockets on pocket facing

• application of pre-ironed pockets in semi-automatic mode

• application of pockets on very small pieces using a special optional stacker

• work on extra long items such as large smock and scrub suit thanks to the space available behind the sewing heads.

Optional devices

BARTACK REINFORCEMENT. Device for applying reinforcement fabric inside the trousers in correspondence of the bartack

LASER MARKER LIGHTS Laser lights to indicate the correct positioning of the pockets.

BOBBIN CHANGER Device for automatic bobbin change with 8 bobbin loader.

BDCAD SOFTWARE Software for creating and editing sewing programs from a Windows PC.

BDCAD PRO SOFTWARE Software for development and creation of templates from Windows PC.

Specifications

| Sewing head |

JAM lockstitch |

| Control unit |

10″ touch screen |

| Feeding system |

Synchronized intermittent feed |

| Sewing area |

From 65×65 to 270×270 mm |

| Folding area |

From 65×65 to 270×270 mm |

| Sewing speed |

Up to 4000 rpm |

| Stitch length |

0.05 – 12.70 mm |

| Average production |

300-320 pockets/h |

| Power source |

220 Vac – 50/60 Hz |

| Electric consumption | Max 1.2 kW |

| Air source | 6 bar |

| Air consumption | Max 1.8 l/cycle |

| Dimension and weight |

200x210x150(H) cm – 550Kg |