JT263HR

Automatic pocket hemming machine for jeans and similar, three needles, chain stitch, adjustable folderThe automatic unit JT263HR is a pocket hemming machine for jeans and similar.

The machine is equipped with:

• Three needle chain stitch KANSAI sewing head with servo direct drive motor

• Intermittent conveyor belt synchronized with the feed dog and powered by electronic motor

• Photo sensors for fabric detecting

• Sensors for thread breaking detecting

• Automatic thread trimmer and vacuum system for thread waste

• Rotating stacker for proper pockets stacking and collection

• JAM touch screen control panel for easy setting of the machine functions

• Electronic control unit developed by JAM

Software updates via USB memory

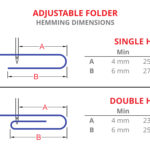

A single adjustable folder allows to realize single and double hem and change the height of the hemming (between 6 and 27 mm).

The machine allows to perform the hemming on different fabric types (from the denim to the stretch) through simple settings and without replacing any device.

The machine is also equipped with a sewing head pull back system and a conveyor belt lifting up system, to make the threading and the most common maintenance operations easy.

Optional devices

AUTOMATIC POCKET LOADER

• Capacity: 400 pockets

• Max pocket size: 270×270 mm

Specifications

| Sewing head |

KANSAI 3 needle chain stitch, direct drive motor |

| Control unit |

JAM PLC + touch screen |

| Feeding system |

Conveyer belt synchronized whit the feed dog |

| Sewing speed |

Up to 3800 rpm |

| Stitch length |

0.05 – 5.0 mm |

| Average production |

1500-2000 pockets/h |

| Power source |

220 Vac – 50/60 Hz |

| Electric consumption | Max 1.5 kW |

| Air source | 6 bar |

| Air consumption | Max 1.5 l/cycle |

| Dimension and weight |

214x100x171(H) cm – 183kg |